Gravel Bike: Designed from the ground up for 3D printing.

Sketch studies were made with regard to the possibilities afforded by 3D printing, such as flowing and bionic styles. However, we wanted to be sure to find a common design language applicable throughout the structure.

For generating new ideas topology optimization software was used to gain a better understanding for the necessary load bearing structures that define that shape of the design. A rough outline of the available space and elements to input the loads were created.

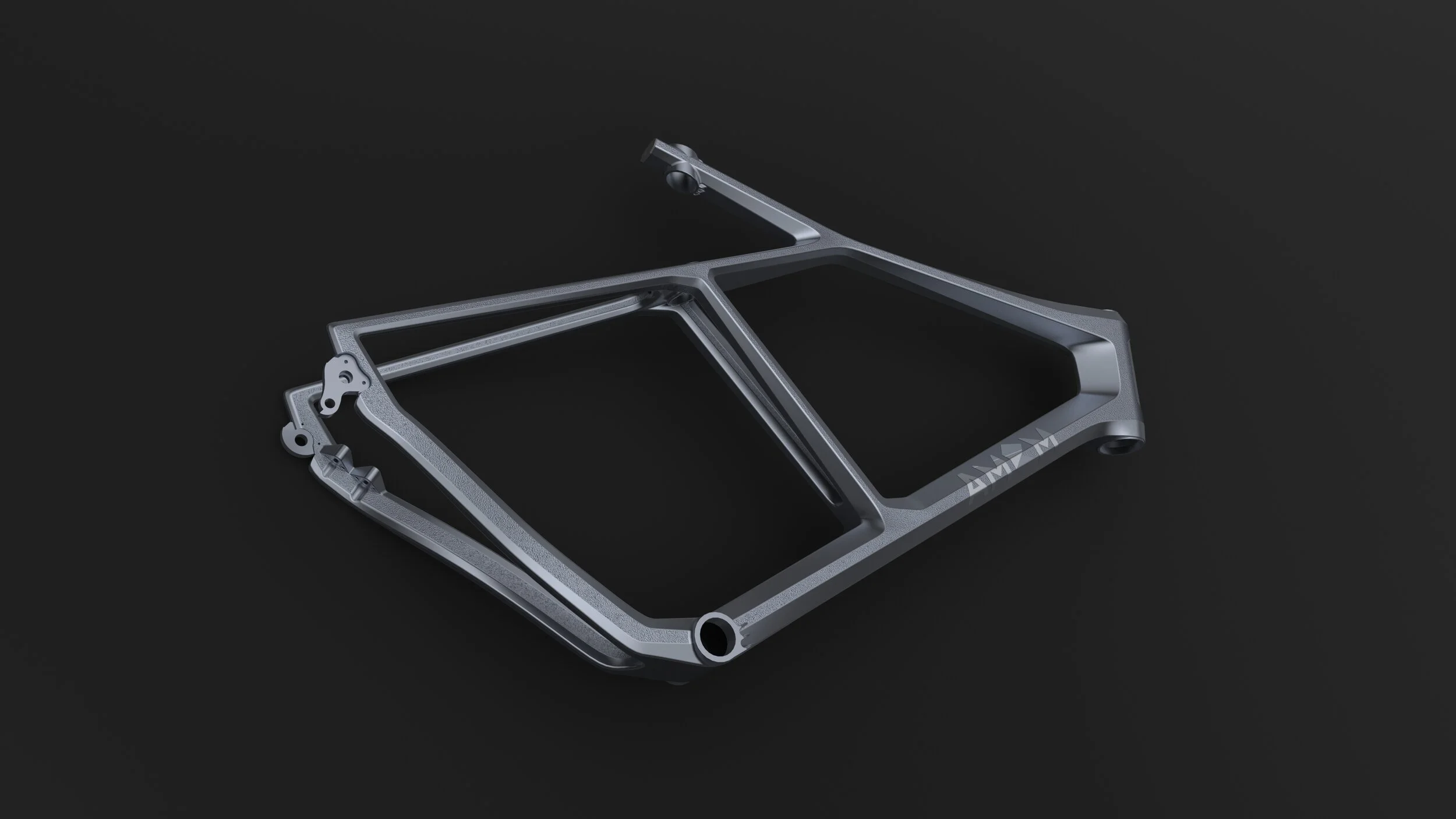

Starting off with very intricate bionic designs mass was removed and shapes refined to create a design striking a balance between styling and additive manufacturability.

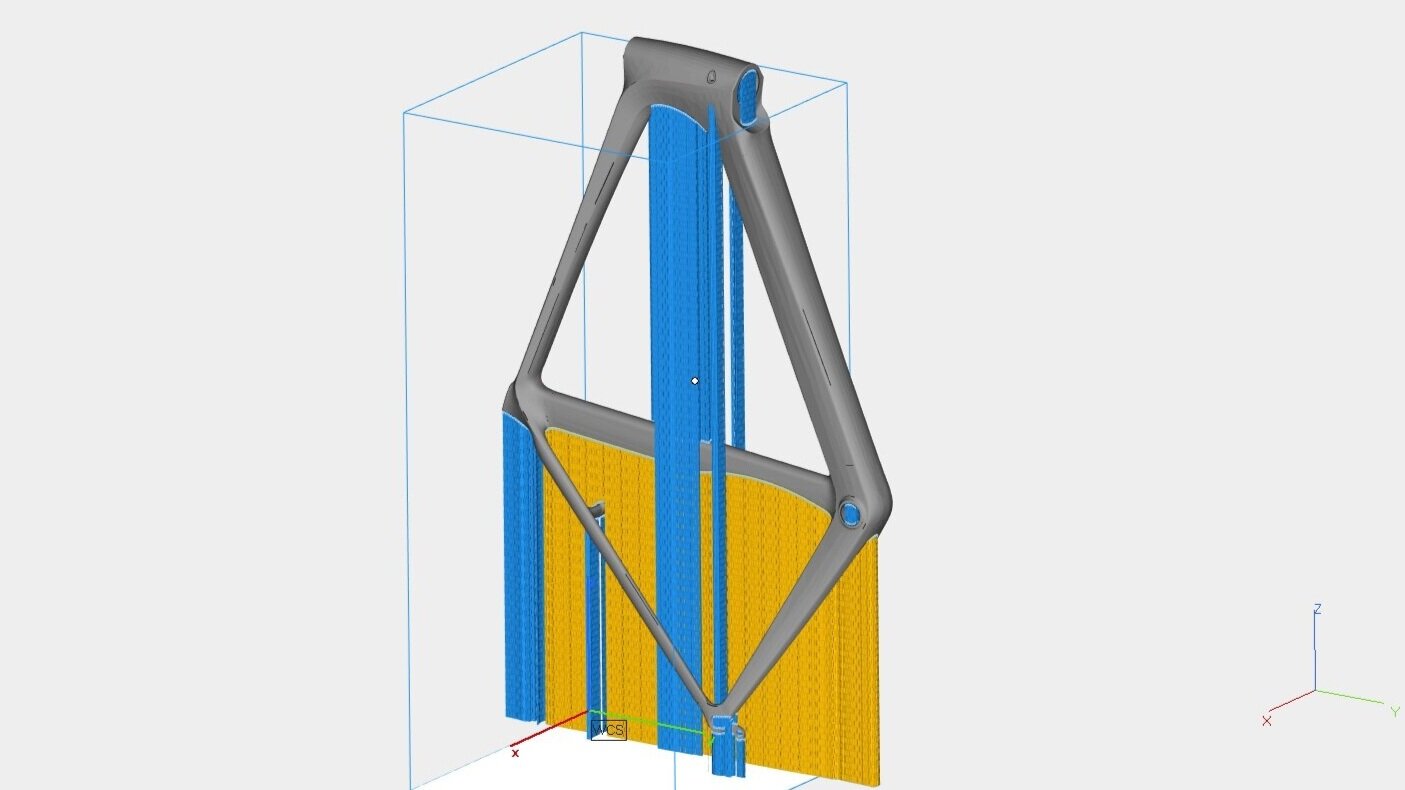

Throughout the design process special attention needed to be paid to the necessary support structures for the part. Reducing these radically would be necessary for the buildability of the frame.

A model of the design was made. However the modelling quality would have to be improved for a working bicycle. Due to software constraints and weight of the part the design was further simplified.

A mock up was made to test buildability. This was created entirely without the need supporting structures. Next, the design was finalized to fit a Shimano GRX810 group settup and wall thicknesses were reduced variably to a resonable stiffness suggested by the previous topology results.

More from the Project...

Bottle Cage

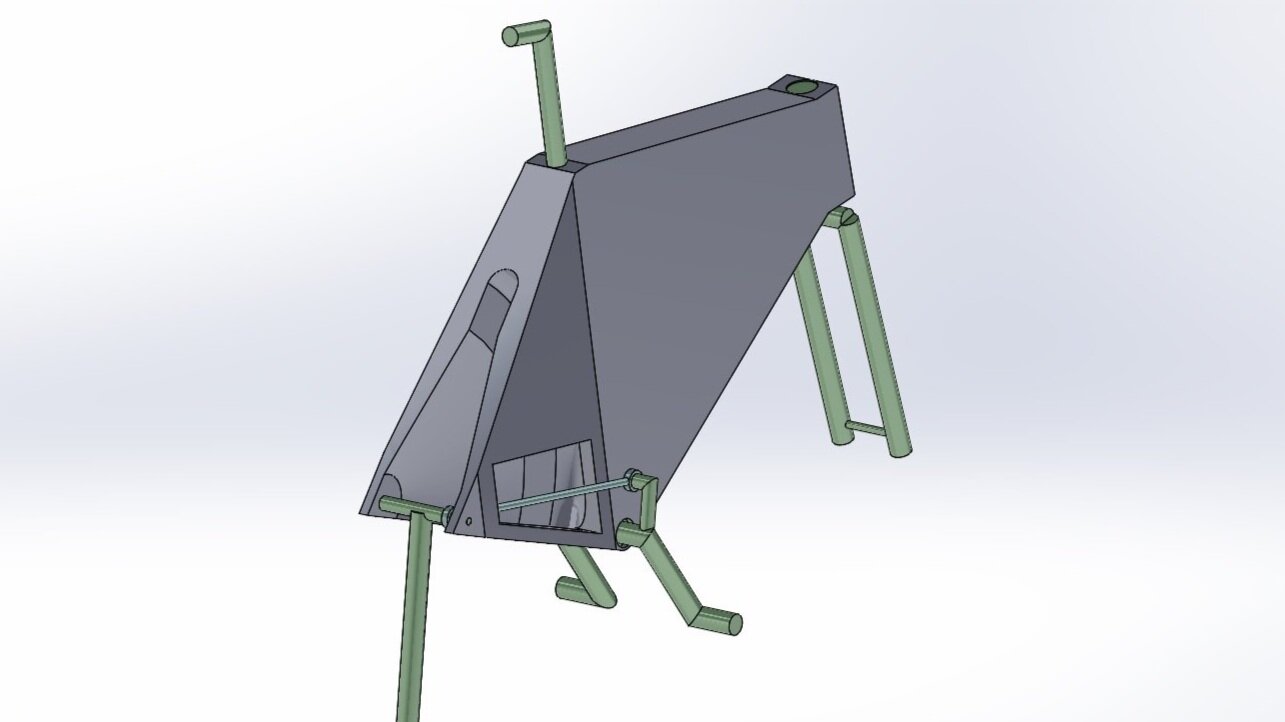

As a side project a bottle holder was designed especially for 3D printing.